Greetings Brother and Sisters,

As winter comes to an end, I wish you all a safe and prosperous spring. All predictions call for another busy year in the construction industry. As the ground thaws, I know our excavation contractors are gearing up for another banner year. For the Safety Corner this quarter, I would like to focus on the regulations and guidance set forth from the Occupational Safety and Health Administration.

As we have seen here in the news headlines, trench collapse is the number one cause of fatalities in the excavation world. Early reports indicate there was an improvement in 2021. But in both 2020 and 2019, 21 workers were killed by collapsing trenches. As with any area where workplace hazards are unique and the risk of life and injury are high, OSHA has a designated Subpart to address them.

OSHA’s answer to the hazards present in excavations is found in the 29 C.F.R. part 1926.650-652 Subpart P. They define an excavation as “any man-made cut, cavity, trench or depression in an earth surface, formed by earth removal.” The first hazard they address is underground installations. The estimated location of utility installations that may be expected during the excavation work shall be determined prior to opening an excavation. The minimum requirement is to call dig safe and have the utility lines marked out. As we all know, those marks are a guideline and not an exact location. The best and most accurate method is “pot-holing.” Many of our large excavation contractors have purchased Vac Trucks to streamline the process of utility location. Badger Daylighting has utilized our members to provide pot-holing services across our area and the entire country.

Access and egress from the excavations are also spelled out in Subpart P. A stairway, ladder, or ramp is required when a depth of 4 feet is reached. Ramps must be designed by a competent person. Means of egress must be located within 25 feet of each other. Spoil piles must be located at least 2 feet from the edge of excavations to mitigate the hazard of falling objects. If an oxygen-deficient or hazardous atmosphere exists or has the potential to exist, the air must be tested before an employee enters a trench greater than 4 feet in depth.

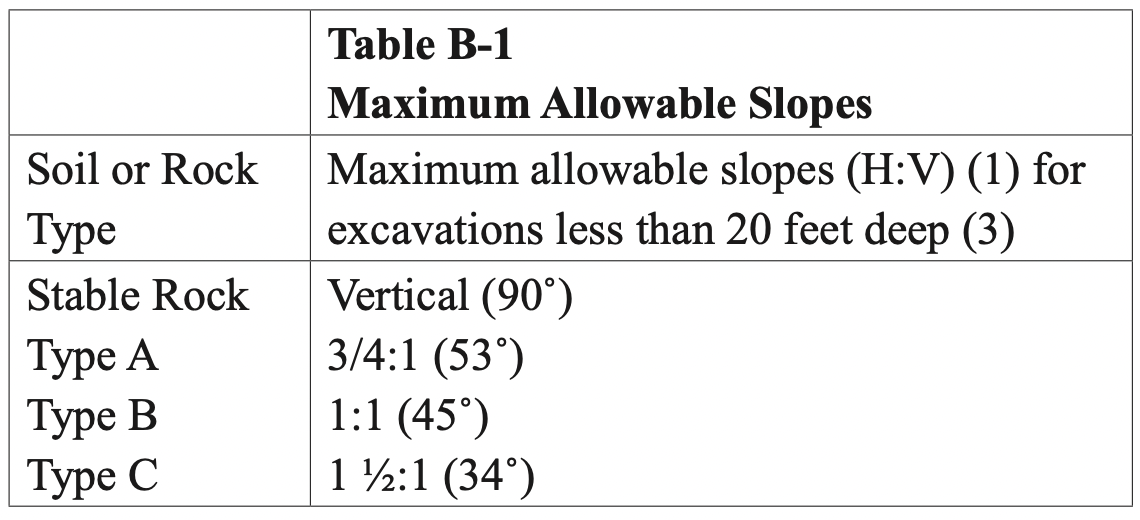

Once an excavation reaches a depth of 5 feet, an adequate cave-in protection system must be employed. The three types of allowable systems are Sloping, Shoring or Shielding. The slope must be meet the parameters of Table B-1, which I have included. Benching is allowed but must also meet Table B-1’s requirements. Shoring systems support the sides of an excavation. Shielding systems such as a trench box protect the worker if a cave-in does concern. As always, if you need any guidance or copies of these regulations, feel free to reach out to Training Center and we will get you what you need. Be safe!!

Co-Safety Officer